Comprehensive Overview of Wire Harness Production and Quality Assurance

Table of Contents

Comprehensive Overview of Wire Harness Production and Quality Assurance #

Wire Harness Manufacturing and Assembly at Chan Ming #

At Chan Ming, we are committed to upholding strict industry standards throughout every stage of the wire harness manufacturing process. Our approach is rooted in close collaboration with customers, ensuring that each harness design is both efficient and tailored to specific requirements. Before moving into production, we verify that the final product will meet UL standards or any other specified criteria.

Design Evaluation and Quotation #

Upon receiving a sample or drawing from the client, our team evaluates the necessary production processes. We design a custom assembly board for the harness, calculate both production and material costs, and provide a detailed quotation. This initial phase ensures that the design is optimized for both performance and cost-effectiveness.

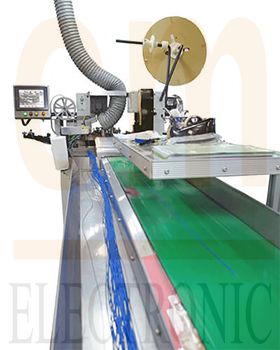

Automated Cutting, Stripping, and Connector Crimping #

Wire harnesses often consist of multiple wires with varying lengths, thicknesses, connectors, and terminals. To achieve consistent precision and quality, we utilize automated machinery for cutting wires to the correct lengths, stripping insulation, and crimping terminals. This automation guarantees uniformity and reliability in the wire sets prepared for assembly.

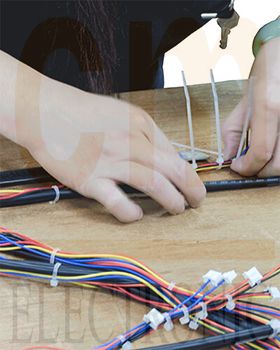

Manual Assembly for Custom Solutions #

Once all component wires are prepared and connectors are attached, the assembly process begins. Given the unique requirements of each application, harnesses are typically assembled by hand rather than through automation. Components and wires are organized in the final assembly area, where they are arranged on form boards specifically designed for quick assembly and product consistency.

Chan Ming’s Wire Harness Manufacturing Capabilities #

A wire harness is a critical component in any electrical application, and its reliability is paramount. Our expertise ensures that each harness is designed with a thorough understanding of its intended environment and the materials involved.

-

Experience: With over 20 years of experience, Chan Ming specializes in crafting high-quality, customized wire harnesses and cable assemblies for a wide range of industries. Our team possesses the knowledge and skills to deliver reliable, durable, and cost-effective solutions.

-

Efficiency: We work closely with clients to ensure that each wire harness meets both the electrical and physical requirements of the application. Regulatory and industry standards are always considered during the design and production phases.

-

Production Capacity: Our facility is equipped to handle large-scale manufacturing using lean, cost-effective processes. We offer a broad product range and the ability to redesign existing products, making us a versatile partner for all harness needs.

Quality Control at Chan Ming #

Quality control is integral to our operations. We adhere to a rigorous company quality policy, ensuring that every product meets strict guidelines and that customer satisfaction remains a top priority.

-

SOP Management: Throughout production, we follow strict Standard Operating Procedure (SOP) management and inspection protocols. Quality control measures include connector visual inspection, pull testing, and electronic signal inspection. Regular systematic evaluations help us maintain and enhance quality standards.

-

Certifications: Chan Ming is ISO 9001:2015 and UL certified. All assemblies and materials comply with RoHS, and upon request, we can provide harnesses and assemblies that meet REACH, CSA, and PSE standards.

Key Manufacturing Processes #

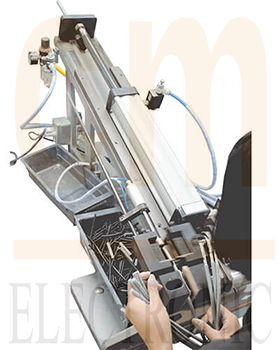

High-Volume Production Equipment #

- Fully Automatic Wire Crimping Machines:

- CPR-ZERO: High volume output at 0.85 seconds per piece (4,200 pcs/hr), capable of dual-end strip and dual-end crimp.

- JNO3S-A1C: High volume output at 0.8 seconds per piece (4,500 pcs/hr).

For further information or to discuss your specific requirements, please contact us.